Spray Error Patternation: A novel approach for spray analysis

Detailed information on spray characteristics is crucial for detecting quality problems in spraying processes and assisting in the design and quality control of atomization devices.

Problem: A limitation of conventional spray diagnostic systems is that only information on specific spray features is provided. The accurate size and location of anomalies within core and periphery of a spray is not assessed. In addition, spray anomalies which may have a major impact on the spray quality in a particular application, may not be detected. Furthermore, there is a need for facilitated spray pattern and plume diagnostics and system calibration.

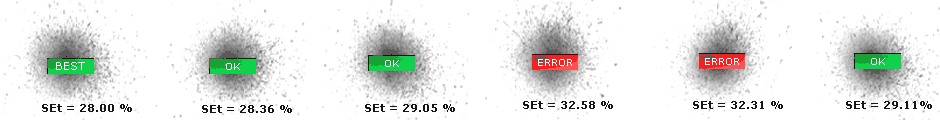

Solution: ioos' patented Diagnostic Systems (Spray Error Patternators) are based on a novel quality control method that facilitates the automated evaluation of data relating to spray surface area, density distribution, and/or mass distribution by visualizing deviations or "Spray Errors" with respect to a specifically generated reference pattern in a two-dimensional plane. Main features of ioos' Spray Error Patternation (SEP) instrumentation include:

+ Enhanced expressiveness of measurement data and detection of otherwise "invisible" spray features.

+ Spray analysis tailored to specific requirements results in improved spray comparison and on-line process control.

+ Analysis of non-circular and asymmetric patterns and specific areas within a spray distribution.

+ Facilitated pattern and plume analysis and accurate system calibration and validation.

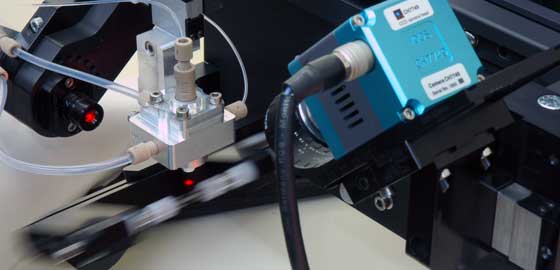

Application example: Spray Error Patternation SEPPAT during coating process